Spark Plasma Sintering (SPS) is a tool/technique to consolidate and densify materials starting from powders. SPS uses pulsed DC currents of up to 4000 A to activate the consolidation and reactionsintering of materials. For this reason, it is sometimes referred to a “field-assisted sintering.” The main advantage of SPS over other consolidation methods is its ability to preserve the nanostructure features of composites. In addition, it is used for the densification of a broad range of novel metallic alloys, semiconductors and ceramics.

Specifications and capabilities of GTAT SPS

- Sintering temperatures up to 2000°C.

- Heating rates up to 1000°C/min.

- Typical sample size of 10 mm or 20 mm diameter. Samples up to 40 mm diameter are possible.

- Pressures from 5 MPa to 60 MPa; can be controlled to ±0.2 MPa.

- Sample can be pressed in vacuum (~10-5 Torr) or Ar atmosphere.

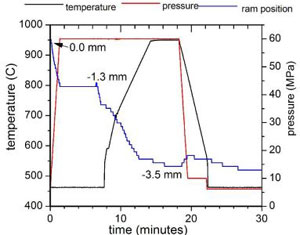

- Data acquisition: Temperature, ram position, and pressure are monitored during the run. Can also acquire current, voltage, ambient pressure (vacuum).

- DC pulse width can be adjusted from 4 ms to 999 ms.

- Ram position can monitored with 0.02 mm accuracy and resolution.

User RatesRates will be based on an hourly or per

sample basis and will be decided after

consultation with the customer.

sample basis and will be decided after

consultation with the customer.

Contact UsDr. Viktor Poltavets

Email: vpoltave@uno.edu

Email: vpoltave@uno.edu

Sample Data